João Restivo, Associate Laboratory LSRE-LCM | March 5 – 16h45 | FEUP Room B035

Student Seminar in Chemical Engineering (DEQ-FEUP)

New findings in water quality have triggered an interest in the development of efficient technologies that can address rising concerns. These include the understanding of the ubiquitous presence of organic micropollutants previously thought absent from water and wastewater, and their harmful properties even at very low concentrations. The pressure of the climate emergency in the management of water for human consumption also creates opportunities for development of safe technologies to facilitate the use or re-use of previously unavailable water sources.

Catalytic water treatment has the potential to address these concerns by promoting the conversion of both organic and inorganic pollutants into non-harmful products in an efficient manner. However, several aspects of their application still require further development if they are to be used in practical situations, ranging from their catalytic efficiency and stability, to reactor design.

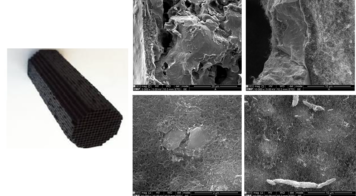

Carbon nanomaterials, and in particular multi-walled carbon nanotubes (MWCNT), are well-known efficient catalysts for the ozonation of emerging organic pollutants in water, and catalyst supports for the reduction of inorganic pollutants. Traditional carbon materials such as activated carbon (AC) are widely known for their catalytic or catalytic support potential. MWCNT have been shown to be able to improve on the performance of AC due to their textural and chemical properties. Moreover, thorough understanding and tuning of the textural and chemical properties of MWCNT allow the design of highly efficient catalytic systems for tailored for the requirements of each specific application. Tt is also possible to design monolithic macro-structures that allow the deployment of the nano-sized MWCNT for real-life applications.

Recently the use of mechanical methods for the modification of MWCNT has been garnering interest. Ball-milling has been used as a method to simultaneously modify their morphology and textural properties, and introduce heteroatoms, resulting in an improved catalytic performance. Ball-milling can further be used to prepare slurries that allow for the coating of cordierite macro-structures with no measurable material loss during application as catalysts.

Various aspects of the preparation of carbon catalysts structured from the nano- to the macro-scale will be discussed. The description of the methodologies will emphasize how working at different scales can affect catalytic performance, and how they can be approached to develop efficient water treatment solutions.

João Restivo is currently a researcher at LSRE-LCM working in project InTreat, with Dr. Carla Orge, Dr. Salomé Soares, and Prof. Fernando Pereira. João completed his PhD in Environmental Engineering with the same group in 2014. Afterwards, he joined the Institute for Materials Discovery as a post-doc at University College London. Later, in 2016, João moved on to the Johnson Matthey Clean Air Technology Centre in Royston, UK, working in the development of gaseous emission control catalysts. In 2019 João returned to LSRE-LCM.

[Host: Joaquim L Faria, Associate Laboratory, LSRE-LCM]

Image credits: João Restivo