Ricardo Santos, Associate Laboratory LSRE-LCM |December 03, 2020 – 14H30 | Online.

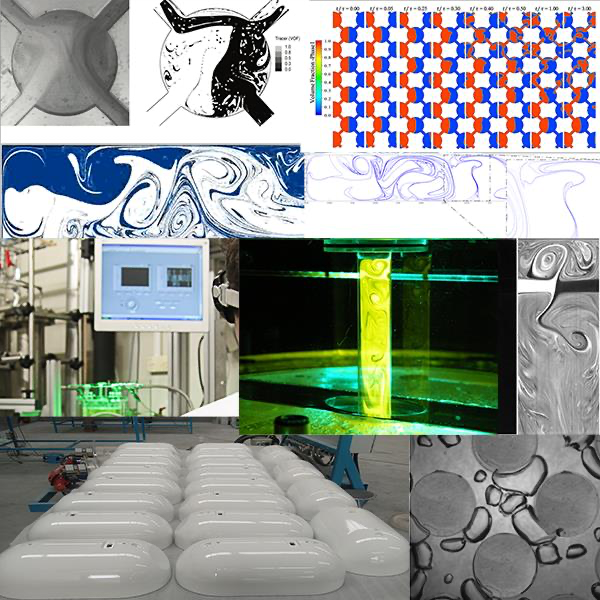

The general perception of chemical reactors is generally associated with two main embodiments: a tank with a stirrer or a pipe. These reactors are still the workhorses of the chemical industry, with particular focus on stirred tanks. The chemical industry in Europe is one of the sectors performing better in terms of reducing its footprint. The energy intensity of this industry was halved in 26 years. One of the main areas of optimization is on mixing operations, particularly those related to chemical reaction and heat transfer. So, the scenario on the chemical reactors has been changing with the introduction of more efficient reactors; many developed from CFD studies.

In the 90s early 2000s, there was a trend on research towards the microsizing of chemical reactors. The microreactors is still a very active research field putting forward technical solutions for fast chemical reactions, or extremely endo/exothermic processes, where mass and heat transfer become limiting steps. Nonetheless, the advantages in most industrial applications are overridden by the operational problems. Prof. Hessel, one of the main promoters of microreactors put it best by stating: “as small as (beneficially) needed, but not as small as possible.”

At FEUP, research on mixing has been proving that mesosized reactors, such as opposed jets mixers and NETmix reactors, can outperform microreactors without most of the associated operational problems. In this talk, I will address the issues of scale in chemical reactors and illustrate it with results from research on mixing and industrial cases.

Ricardo Santos graduated in Environmental Engineering at Universidade de Aveiro in 1996 and got his PhD in Chemical Engineering from Faculty of Engineering of University of Porto (FEUP) in 2003. The PhD was made at LSRE and the research topic was: Mixing Mechanisms in Reaction Injection Moulding. After the PhD he was Post-Doc for one year, in an industrial project on the rheology of Self-Compacting Concrete. Since 2006 he has been at the LSRE-LCM Associated Laboratory as Research Assistant researching on the field of mixing in chemical and biological reactors. One of his main fields of interest is the mixing in reactive polymerization reactors. In 2013 he was one of the founders of a spin-off company, MICE-molds, that is taking to industry the main findings of the research on Reaction Injection Moulding at the LSRE-LCM. Recently, he has been researching on mixing in NETmix reactors, in single-phase and multiphase flow for environmental applications. Since 2017 he is the leader of a research project funded by FCT on this topic (HXmeso).

[Host: Joaquim Faria, Associate Laboratory, LSRE-LCM]

Image credits: Dânia Constantino